Trailer Drawings

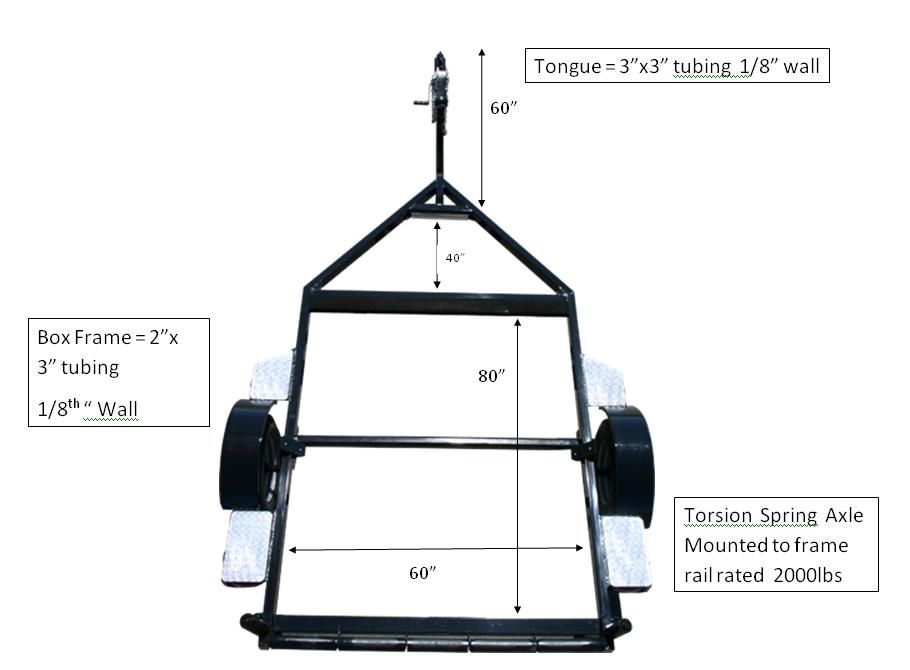

Just wanted to share the trailer drawings I mentioned a while back. Might be useful to someone who is looking to build one from scratch. The drawings are not complete as there is no tongue, lights, or axle/wheels. But, the most difficult part of building a trailer is making decisions on overall size, etc.

We have also made some separate detail drawings of the flip-down trailer stand we are showing attached in the drawings.

The measurements for this drawings came directly from my drift boat trailer, which is a manufactured trailer, but I do not know the maker. Please shoot any questions you might have as it would be fun to work through them with my students.

More to follow as we detail out the drawings.

First is a rendering, should show on your screen. Then, two drawings (one with dimensions in .pdf form)

Tags:

Replies to This Discussion

-

Permalink Reply by Rick Newman on March 22, 2013 at 10:07am

-

Vance don't you have at least two days of summer up there? About July 21st?

Rick Newman

-

Permalink Reply by Vance Wonser on March 22, 2013 at 10:20am

-

Yeah but I planned on doing the finish on my boat those days... :-)

Last year I had to do a spring hanger repair on the trailer so I could go get the Don Hill to bring her home. Just 5 minutes of welding... It was raining hard so I pulled it up as close as possible to the garage (full of stored stuff so u can't get trailer in) laid one piece of plywood over the trailer to keep the rain off me & the weld while I laid on cardboard in a puddle to work I love coastal Alaska.... Man do I miss my growing up area in Klamath Falls OR at times like that!

-

Permalink Reply by Rick Newman on March 22, 2013 at 10:25am

-

Just spray it with bug dope, you'll never need any when you are fishing!

Rick

-

Permalink Reply by Phillip Westendorf on April 1, 2013 at 8:42pm

-

Vance,

If you post a few pics of the trailer as it is, there are several people on this forum who'll be happy to provide their ideas on how to go about modifying it.

Mike Russo's pics at the top of the home page is as good as an example there is. You can take several ideas from them.

Dorf

-

Permalink Reply by Vance Wonser on April 2, 2013 at 11:25am

-

I will try & do that soon Dorf. Little too much snow in the way right now... You can get a bit of a look on my picture page.

-

Permalink Reply by Andrew on March 22, 2013 at 11:45am

-

Nicely done.

I have been drawing some plans (not nearly as nice as yours) in preparation of having a trailer made which will be a Hyde trailer clone.

Here is what the Hyde measures up at.

About the only thing that I notice is the joint where the cross member meets the side rail that goes out to the tounge might be tricky to fabricate.

About the only thing that I notice is the joint where the cross member meets the side rail that goes out to the tounge might be tricky to fabricate. If you look at a Hyde trailer the cross member meets the side rail at a 90* angle, and then the 45*angle goes off from the top of the cross member with a little wedge added for support.

Now I just need to find someone in Calgary that can fabricate it for a reasonable cost.

Andrew

-

Permalink Reply by Tom Anderson on March 23, 2013 at 12:07pm

-

I just got back online this morning and appreciate all the great responses. I'm still trying to figure the forum thing out, and have decided to respond to all posts since my last here in one at the end of the string:

Tungsten; You are welcome. I'm new to all of this and have learned a lot from reading through everyone's posts, and hope to be able to contribute to the cause. I know this post is not about the wooden boats themselves, but gotta have a proper trailer to sport those beautiful boats around on right? Maybe I'll start working on a laminated wood-framed trailer??

Rick; Great questions! I could make a project file/worksheet right off of you list of questions. I think the most important being questions about spring rates/loads, axles, etc. One thing about torsion springs that I've been considering is that one of their best features is that they keep the trailer/load lower to the ground, which is actually a disadvantage at many of our 'launches'.

Dorf: Good thoughts! I agree with locating tie downs adjacent to the support points (cross rails). This is common practice with strapping down loads on stickers in the building world. You can really quickly add lots of pressure with ratchet straps especially and can cause undue stress on the boat hull if not located directly over a support.

I don't think Oregon requires trailers as small as these to be licensed, but Washington definitely does. My wife and her father happen to run our local DOL agency where vehicle licensing happens, and we have to get home-builts inspected by the Washington State Police.

Nice work finding the custom axle shop. I'm sure I'll be able to find something in the Portland area similar. I'd like to see photos of how yours turns out.

Brian: I like that idea . . . I too only use one strap most of the time as the winch strap at the bow does a pretty good job up there. Then I locate one strap over the gunwhales directly over the rear cross-support. Some gnarly steep dirt roads I'll throw a second strap over the front.

Vance: We will definitely end up building one, but probably not until next year when I'm looking to build a boat with my woodworking students, and then the trailer with the kids in my Metalworking/Welding class. I've got to figure some fund-raising between now and then. And, we will try and post a Blog on both builds next year. Should be fun.

Andrew: Those dimensions don't look too far off from the ones we've got in our drawings. Note the main difference in the front end of the trailer. I think I like the structure of the Baker trailer a little better where the 3x3 tongue piece extend right back to the main front cross-rail. It really shouldn't be too expensive to have a welding shop fabricate the frame. There's not that much too it really.

Looks like the Hyde roller is segmented short rollers.

Please keep the great feedback and ideas coming, I really enjoy it . . . and it's also feeding my fishing bug here while we're waiting for things to happen here. Talk soon.

-

Permalink Reply by Rick Newman on March 23, 2013 at 10:04pm

-

It's quite remarkable as to the depth of knowledge the folks on this forum have. Larry your idea for a torsion axle is pretty cool. I've never seen one or read of one like you describe.

When I worked at a marina where we had to troubleshoot light problems grounding or should I saw a lack of grounding was a common cause. However I have found many other issues too. Bad bulbs, dirty bulb contacts. cold solder joints, chaffed wires creating shorts to the frame, bad seven to five adapters, loose wires within the female socket, reversed wires, non-standard wiring (use what ever color you want with disregard for standards, etc. The press on connectors that need to have a plate pushed through both wires to make a connection can sometimes fail to make the proper connection, the five wire plug can have corroded or dirty contacts, wires can also become corroded or oxidized, and so on.

I suggested the trailer light troubleshooting is an important skill that is infrequently taught or considered. Sort of like backing a trailer up or crossing your safety chains to support the trailer tongue if you forget fasten the latching mechanism or if you overlook the fact that the hitch requires a 2" ball and you were trying to use a 1 7/8"!

You can also do some trouble shooting by setting the trailer tongue on the negative terminal and running a wire from the questioned connection to the positive terminal to see if the lights work.

Good luck on the project.

Rick Newman

-

Permalink Reply by Andrew on March 24, 2013 at 6:50pm

-

Having launched more than a Hydes it depends on the trailer. Some of them have a bunch of short runner rollers like the one in the picture, and others have a full length roller along the entire back. I prefer the full length verison.

I agree with you on running the the tongue all the way back to the cross member.

The place where I plan having my axel built also builds custom rollers, so I will have them do one for me at that time.

Here in Calgary I have got quotes from $700-$900 just for the welding. Seem a little high.

By the time I have one built I can just buy one from Hyde for $1500 at that price.

Andrew

-

Permalink Reply by Andrew on April 4, 2013 at 10:24pm

-

Tom,

I gave your plans to my welder and he should have it welded up shortly, between paying jobs.

A question that I have is does anyone know the angle of the torsion axle commonly used on db trailers? 10.5* or 22.5* below? I am leaning toward 22.5* based on pictures I've seen, but I want to make sure I order the right one.

Thanks,

Andrew

-

Permalink Reply by Tom Anderson on April 5, 2013 at 8:20am

-

Hey that's great.

I'll be curious to know how it goes. I think I mentioned before that I did learn that the trailer we took dimensions from is indeed a Baker, so should be a 'tried and true' design.

About the angles of the axles . . . depends on who you ask I suppose. It seems as if Torfelx claims that ride 'quality' is best with their standard 22d-below axle. But Dexter claims no difference between their many choices.

Personally, I think the ride difference is probably negligible, and at least secondary to the desired ride height. One of the big advantages of torsion axles over springs is the ability to set the trailer frame lower to the ground . . . important for some campers, and any kind of deck-over trailer like a snowmobile trailer and such. For me, I actually like the idea of having a little extra clearance between the ground and my drift boat trailer frame for all the nasty launches we seem to have here in the PNW. Granted, you've got to get your boat up onto a higher frame/roller when taking out.

There was a good discussion with diagrams of calculating heights on some forum for guys who build teardrop trailers. I'm actually going to use some of this for a quick little real-life geometry lesson with my CAD design students at some point. It's quite simple when you break it down: Center of axle height based on 'Static Loaded Radius' of you given tire (accounts for squish of tire on ground), axle 'anlge' and trailing arm length (here's the geometry) which then allows you to figure height to top of axle bracket or bottom of trailer frame. Fortunately Dexter Axle publishes spec sheets on these for all their Torflex axles.

Some links to look at:

Teardrop Trailer Guys Forum: Torsion Axle Discussion

Dexter Axles (information request page): Dexter Axle Info. Request Page

I'll try to upload the Torflex Axle Spec bulletin in .pdf next:

Keep us posted on how the build goes.

Thanks, Tom

It would be interesting to see how much the frame weighs when they are done (as in the drawings without tongue, angled-guides, or axles. I don't remember the number right now, but we did use Inventor's iProperties funtion to calculate it. I'll look it up when we're back in school (spring break right now).

- Attachments:

-

-

Torflex_Information_12-10.pdf, 1.9 MB

Torflex_Information_12-10.pdf, 1.9 MB

-

-

Permalink Reply by Andrew on April 5, 2013 at 7:43pm

-

That's great information.

I was thinking the same thing about having some additional clearance with 22* down axle. Although most of the launches we use are not too bad having a couple extra inches wont hurt and the winch can handle the heavy lifting.

I'll post some picks when I get some.

Andrew

© 2026 Created by Randy Dersham.

Powered by

![]()