Tips for Flat bed trailers

For the roller, I have a length of 1.75" galvy pipe out back of the house. Anyone got a better play by play on how to mount the bearings in the pipe and Then how it would attach to the side mounted brackets on the trailer already? I think if I can find the bearings I might be able to make one on the cheap. Gary over at mtn driftboat in victory has a full roller setup for like $80 from Adams trailers, so I'd need to do it real cheap to sacve much money. It looks simple though, anyone got tips on making a roller with that length of pipe I have?

Tags:

Replies to This Discussion

-

Permalink Reply by Rojo on June 11, 2013 at 1:33pm

-

I was going to say that I remember some guy posting that you could buy pvc pipe a gauge or two bigger than the galvanized and use that as a roller, but then i looked up the comment and saw that it was you that posted that comment...

-

Permalink Reply by chris towles on June 11, 2013 at 3:44pm

-

Yeah, that original one worked good but I used maybe too small a diameter inner pipe and over the last few years from being on and off the trailer every day its gotten bent and the roller no longer rolls. My buddy built one on his raft trailer and that one is stile working good, but I think the stem bent mine getting rammed into the pipe and then up onto the trailer. I'm looking for something a little more like what I have seen commercially and also recently in some of the other posts. Here's a few pics

https://lh4.googleusercontent.com/-tKM3JIEJi6w/Ubejp62h7nI/AAAAAAAA...

https://lh6.googleusercontent.com/-vBTXbcKd_uM/Ubek0BRiD0I/AAAAAAAA...

https://lh5.googleusercontent.com/-z2qkIklTub0/UbejrkO_UhI/AAAAAAAA...

-

Permalink Reply by Phillip Westendorf on June 11, 2013 at 6:48pm

-

Chris,

Just posted this a week or two ago. Take a look. You can't get a roller much lest costly than this.

http://www.woodenboatpeople.com/profiles/blogs/db-trailer-roller

Dorf

-

Permalink Reply by chris towles on June 12, 2013 at 8:25am

-

I did see that but trying to decript the drawing was like reading stereo instructions for me. I have looked it over a few times at length now w the picture and think I see what's going on. So those bearings w the snap ring press into the ends of your length of pipe. The washer on top is a 5/8" hole fender washer probably stainless to keep the bearing in the end of the pipe. That 5/8" bar is steel? Called crs? And it runs the entire length thru the center of the outer bar and u drilled hole for the cotter pin?

Most of it looks doable but sofar I have not had much luck finding bearing that will fit my 1 3/4" pipe. The only one I seem to find easily is the 5/8 I'd x 1 3/8" one u referenced at tractor supply. Where do u find that solid metal bar for the center? Is that stuff easy enough to cut with a grinder and drill the hole for the cotter pin?

-

Permalink Reply by chris towles on June 12, 2013 at 9:20am

-

Ok, a quick update and question. The pipe that I have is 1 3/4" od and looks like a 1 5/8" id, which means the wall size is only 1/16" thick. Looks like galvy fence post or conduit. Is this wall size too thin to support the weight of the boat. Will the pipe bend with the weight of the boat? And if so, what wall size should I look for if I go looking for one

As I said before Gary at mtn driftboat has cheap rollers at like $45 for the roller and bearings, and $35 for the mounting plates . If I have to buy more pipe it may make the cost difference negligible and I might be better off spending my time fighting other battles...like getting this boat done which is way behind schedule.

-

Permalink Reply by Andrew on June 12, 2013 at 12:27pm

-

I know what you mean about getting the boat done. It seems that the last little bits take the longest.

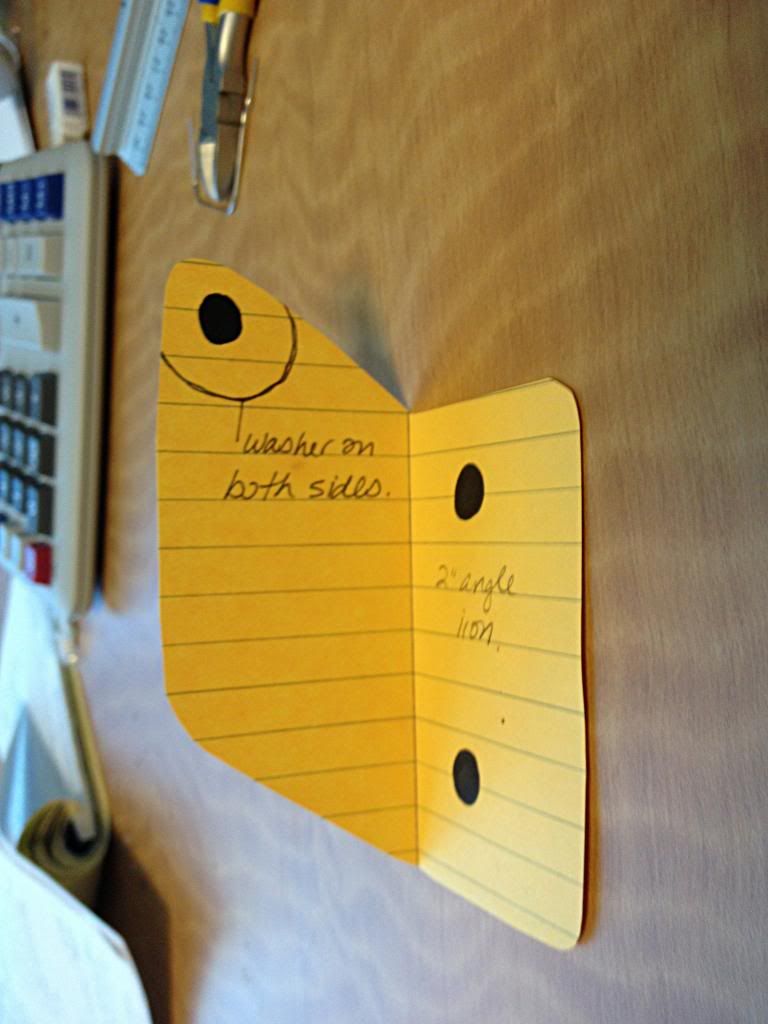

Here is an idea for a bracket that I was planning on using to mount my roller. It'll be made out of some thicker 2' angle iron. The black dots are where it will both to the trailer, and then the hole for the bolt on the roller assemble to go through. There is no welding needed, just some time with the grinder and cut off wheel.

I plan on bolting it to the rear cross member of the trailer in this orientation.

I am planning on using a flanged bearing like this one with a bolt going through it. The head of the bolt will go through the small end of the baring which will be inserted into the pipe, and through the bracket and a nut applied.

I'lll do up a sketch and post it here for clarity.

-

Permalink Reply by Phillip Westendorf on June 12, 2013 at 3:28pm

-

Chris,

The pipe I used is 1 1/4 Galvanized Electrical Conduit. It's Schedule 40 which is 1.66" Outside Dia, 1.38 Inside Dia. resulting in .14" wall thickness. It has the same Dimensions of Black Pipe (gas, water, air). It's available @ Home Depot, Lowes, or any Electrical Contractor. It weighs 2.27# per foot. At approx. 60-64" will be more than enough to handle the stress/strain of the Drift Boat.

The bearings @ 1.375 OD are a slip fit into the pipe (1.380 ID) so I added a layer of masking tape (3/8" wide) on the bearings OD to make it a light press fit.

The 5/8 Dia CRS is "Cold Rolled Steel" is a common mild low carbon steel used in tool shops. I purchased it from Peerless Steel Co, a local steel supplier. I bought a full bar (12' lg. as it avoided a cutting charge. It's common and readily available and sold by the Lb.

The washers are Std. SAE Flat Washers in Stainless from Tractor Supply Co. I filed a flat at one end of the rod, drilled a 1/8" dia cross hole there and used a std. cotter pin. Then assembled the whole mess and marked the location of the cotter pin at tehe other end and then drilled it.

I made a similar bracket to Andrews as shown below. I just welded two 1/4 x 2" wide steel pieces to form the angle bracket. The two brackets should be one "Right Hand" and the second a "Left Hand".

Hope this clarifies the sketch.

Dorf

-

Permalink Reply by chris towles on June 13, 2013 at 1:00am

-

Thanks for the follow up. U guys do really nice work. All the recent trailer threads have shown some nice diy work. The welding is a bit over my head but if i Can cut it w my grinder and drill it to shape I can fabricate it out of metal. I think my pipe might have a bit too thin of a wall but I guess we'll see. i didn't have much luck on the internet finding the right snap ring bearing for my size pipe, but a trip the the car parts store got a call into the bearing company. That guy said all the drift boat raft frame guys are going to nylons of uhmw bushings. At only $2 apiece it was worth my risk. Ill try and install them and see how it goes. If it looks like it will work ill find a length of 1/2" cars which will fit the inner hole of the bushing I bought. Looks like a cheap low risk option since I already have. If it turns out to be mess I may buy a bar from mtn driftboat and try to rig my current mount plate to take the new bar. Kmart was out of cheap trailer light kits so I may have to hit eBay up. I'd like to go led but can't quite justify the expense right now with building the boat and all. Ill keep all posted with the roller progress.

In the meantime any body got any tips of running a flat bed. Thinking of doing a small 5' wide x 4' deck in the center for the boat to sit on . Ill leave the front bunk in place and probably brace underneath it. Thinking of thin uhmw cutting board strips front to back to help the boat slide off easy. Ill counter sink the heads and attach nuts in the other side so I can adjust to tight as the heat expands and contracts the plastic over time.

-

Permalink Reply by Rick Newman on June 13, 2013 at 6:42am

-

Chris, my trailer came as a flat bed. Like you, I faced monetary challenges and had to compromise. The trailer was originally made for a pram. It had a perimeter frame topped with plywood. I went to Home Depot and bought some $5 a running foot outdoor carpet. Five year guarantee. I just glued the carpet down and replaced the stainless steel screws in their holes. This was after my friend and I sanded the frame. I primed and painted it black. Like Phil I drilled holes and rewired the frame with tubing through holes and shrink tubing and grommets. Soldered connections and trailer lights from the auto parts store.

So far so good, I can't find my pictures of it, they are on one of my other computers. I don't remember the dimensions of the bed but estimate it is 4' x 6'. The only issue I have is my boat shifts from side to side so I need to add some guide strips along the side. I have a couple of pieces of plastic decking material that I can cut to length and place along the sides of the intended path of the boat. I have left over carpet I will attach and then bolt down the plastic as appropriate. The trailer already had a roller. I had to have my neighbor lengthen the winch stand, that cost $20.

If I can't find the pictures I will take some more if you want.

Rick Newman

-

Permalink Reply by Andrew on June 13, 2013 at 10:42am

-

That's just what I'm going for Dorf. I don't weld so I have to make mine from angle iron.

I think the conduit you were referring to was 1 1/2" not 1 1/4". I dont think they make 1 1/4".

Andrew

-

Permalink Reply by Phillip Westendorf on June 13, 2013 at 5:59pm

-

Andrew,

The pipe is 1 1/4" Schedule 40. See attached chart with dimensions. You may be referring of the commercial conduit (Home Depot/Lowes elec. Dept.) that is used in homes, etc. That stuff is real thin wall. Schedule 40 is Industrial and used to meet NEMA specs., a heavier wall per the chart I refer to & is found in the plumbing dept.

http://www.engineeringtoolbox.com/ansi-steel-pipes-d_305.html

The angle Iron bracket will work, you just have to cut away the parts you don't need. I made all the pieces from 1/4" x 2" Flat Stock cutting them with a 4 1/2" grinder with a cut off wheel. and another with a 4 1/2" dia grinding wheel.

To keep the boat from sliding side to side, consider bolting a piece of 2 x 4 lumber on edge with long carriage bolts (3/8" dia ) and covering it with a piece of carpet (like Rick) or use the plastic you referred to line the contacting surfaces with the boat.

Dorf

-

Permalink Reply by chris towles on June 13, 2013 at 7:47pm

-

I'm pretty sure the pipe I got is the electrical conduit. It's got a wall thickness of .065 . Wonder if this is burly enough. I'd like to do this just one time. Seems like if I could find a length of 1 1/2 schedule 40 these same bearings might work. Might make a few calls before I contact cement the plugs in the pipe I have.

© 2026 Created by Randy Dersham.

Powered by

![]()