Tips for Flat bed trailers

For the roller, I have a length of 1.75" galvy pipe out back of the house. Anyone got a better play by play on how to mount the bearings in the pipe and Then how it would attach to the side mounted brackets on the trailer already? I think if I can find the bearings I might be able to make one on the cheap. Gary over at mtn driftboat in victory has a full roller setup for like $80 from Adams trailers, so I'd need to do it real cheap to sacve much money. It looks simple though, anyone got tips on making a roller with that length of pipe I have?

Tags:

Replies to This Discussion

-

Permalink Reply by Phillip Westendorf on June 17, 2013 at 7:14pm

-

Chris,

Here's the mechanical data on the Elec. conduit you have.

http://www.electrolinkltd.com/electrolink/ladder/66.htm

There are no mechanical properties listed only dimensions. If you want to know more you'll need to purchase the NEMA Spec for EMT Conduit and it's $ 57.

So Keep going, it'll let you know if it's "Burley Enuf".

Dorf

-

Permalink Reply by Andrew on June 14, 2013 at 5:39pm

-

Oops. Reading has never been my strong suit.

That is great info.

Andrew

-

Permalink Reply by chris towles on June 13, 2013 at 7:32pm

-

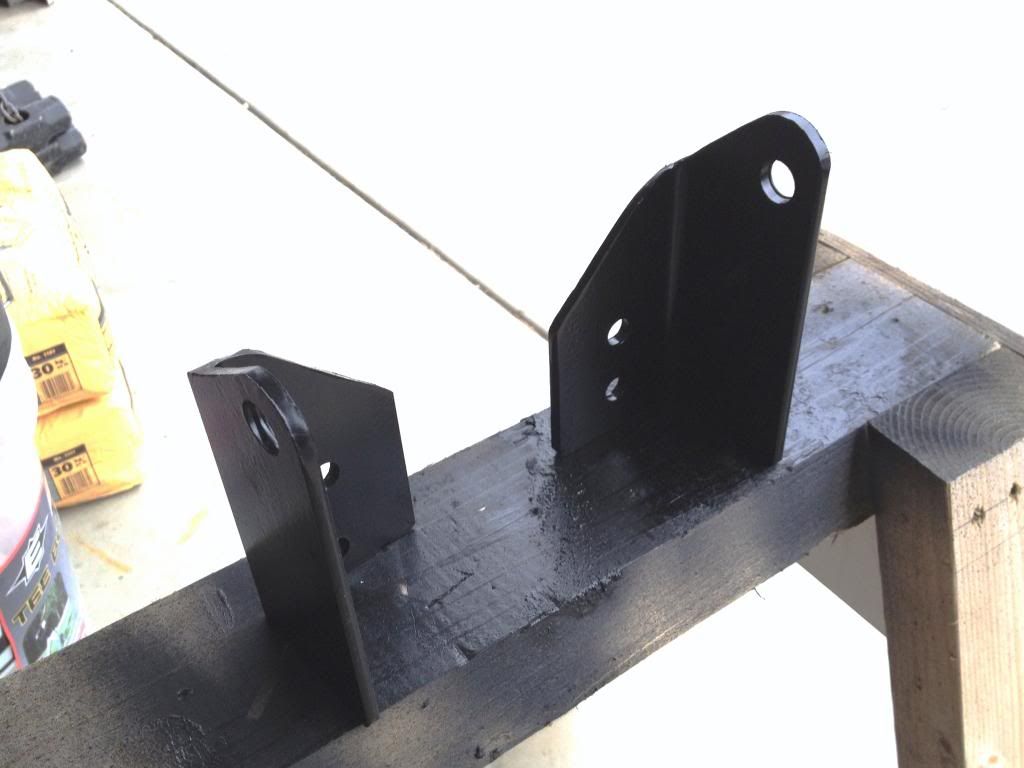

Heres what I got for the bearing. They were only 2.40 apiece but the overnight shipping the parts store got cost me about $11 so not really so cheap in the end but it looks like these will work and they fit good in the end of the pipe. Ill use contact cement to hold these plugs n the end of the pipe. Still looking for a 6 ft length of the 1/2 crs steel bar. All I have found locally is a 4 ft piece but the roller brackets are about 5 ft apart. The holes in my mount arms are worn oval and do not look that sturdy. My plan is to find some thick heavy steel fender washers with a 1/2 center. Ill pull the bar up to the top of the ovalized hole, then have the welder weld the washers on either side of the hole. From the arm. Then I can just measure the tube to fit the inner length, plug and go. I also thought about having the welder tack on a nut or cap on one side of the bar so I can just drill one hole for the cotter pin.

For the deck I realized today I made a dumb mistake. My boss had me haul a load of rhino deck to the dump this winter. It was a few odd lengths. I was hesitant to salvage it cause at the time I didn't think of the fact I could have decked the trailer with it. Oh well, gotta find something different now. Probably ply with some uh w strips seems like the easiet - Attachments:

-

-

image.jpg, 1.5 MB

image.jpg, 1.5 MB

-

-

Permalink Reply by Eric Loudenslager on June 13, 2013 at 6:47pm

-

Seems like Rick has had a few challenges with a flat bed trailer......you might want to figure out whether you can eliminate the plywood bed and have the boat rest on the trailer frame fore and aft.

My drift boat trailer is designed so the boat rides up onto the trailer using the roller, but then nests into two frame elements. If my boat were resting on a piece of plywood it would be sitting in the center on one point with the stem and transom unsupported. As it is now, there are two resting positions. Resting on a single point would result in a lot more sliding around, in my opinion.

-

Permalink Reply by chris towles on June 14, 2013 at 9:54am

-

U might be right and maybe I am over thinking this one trying to reinvent the wheel here. A google search for drift boat trailers yielded lots of results of bunked trailers, no flat beds. My plan was to have a small bed that just supported the boat in the middle of the flat spot, and use side bunks to keep it from slipping side to side. Since I still would need to find and buy plywood maybe I am better with bunks and I have scrap wood to make those out of. Next question is what to cover them with. The Capet on my old one tore up my battens with the on and off of the trailer everyday. The new boat is s and g w no battens but I have not forgotten the wear from the others. I'd like a better alternative. Still thinking that rhino deck stuff I threw away would have been the best bet. Oh well, live and learn.

-

Permalink Reply by Rick Newman on June 15, 2013 at 7:05am

-

Well since my boat is named "Challenge" isn't that fitting? It tows extremely well and backs up easily. Time will tell if the carpet over the plywood is a good idea. Given the hurry up and get the boat on the road to the Festival and my budget at the time it works well. The majority of the bottom is supported and the boat slides right on and off. Original price was $400.

Rick Newman

-

Permalink Reply by chris towles on June 15, 2013 at 8:51am

-

My boat has a pretty decent flat spot, although its not exactly flat since there is no parallel chine. I figured a flat bed would better support the boat. But it sounds like I may be in for more problems than I anticipated. Luckily I haven't done any work or bought anything for that part of the trailer yet.

Yesterday I spent the day talking to every know it all welder in town. Usually I would get a confused look on what I was looking for or trying to do, then some lecture about how I was doing it all wrong, and then a speech about how they were the best....yada yada. Took 7 different stops between the fence guy, the plumbing supplier, mechanical suppliers, and welders. Finally the last guy I went to did know what he was talking about and sold me the 1/2" round was looking for $5. The previous welder I talked to told me it was 12.50 a foot...jeez. Getting galvy pipe here is just not affordable. All the schedule 40 I found was like $8 a foot. The welder guys told me to use black iron pipe and paint it. They might be right. One guy has some at like under $4 a foot, but by the time I buy that pipe and then have him tack a plate on each arm to make the mount hole 1/2" ill probably b in over the of just buying a new one. I knew this project was probably not worth the trouble.

I'm just gonna try and cut my losses here and use my conduit. I put the 10 ft length between the picnic table and the ground and stood on it. Took my weight pretty well. A little flex but not too bad. Ill stick some 1 5/8 washers I got with a 1/2" center hole and jb weld them into the centers of the pipe then put bike grease in the center hole. Hopefully these will support the outer bar in the center of the length.

-

Permalink Reply by chris towles on June 18, 2013 at 11:20am

-

That looks good. I like how you mounted the bolt with nuts on either side.

Im at a standstill on the trailer at the moment. I need to have the welder tack plates to my mount arms to take the 1/2" crs center bar. Im also wIting on some parts. I got a good deal on ebay and spent the extra $10 for led lights in the rear. For the side markers ill just use the cheap incandecent ones available locally. Sounds like there may be a few scraps of that composite decking at the shop still, so i may grab those and try and make them work for bunks. That stuff is kinda flexible so ill probably frame the bunks with vertical 2x4 then cap the tops with the composite decking. I also want to mabye have the welder put on a few l bracket braces so i can mount some plywood steps on the side in front and back of the wheel wells.

-

Permalink Reply by Vance Wonser on July 3, 2013 at 2:48pm

-

Chris, sounds like you won't be using the bushings you purchased? Can you give me the dimensions? I may be able to make use of them.

- ‹ Previous

- 1

- 2

- Next ›

© 2026 Created by Randy Dersham.

Powered by

![]()